Monocrystalline vs Polycrystalline Solar Panels

Understanding the differences between monocrystalline and polycrystalline solar panels remains important for UK homeowners and businesses, particularly when evaluating existing systems or understanding older installations. Whilst both technologies convert sunlight into electricity effectively, they differ significantly in manufacturing processes, energy output, appearance, and performance characteristics.

This comprehensive guide examines the key differences between these two crystalline silicon technologies, helping you understand panel types and make informed decisions about solar investments. For those considering new installations, our step-by-step solar panel installation guide provides detailed insights into the complete process.

Important Market Update: Polycrystalline Panels Discontinued

As of 2023-2024, polycrystalline solar panels are no longer manufactured by major solar panel producers. According to the International Energy Agency (IEA), monocrystalline technology now accounts for approximately 98% of global solar cell production, with polycrystalline panels having effectively disappeared from the market.

This guide remains valuable for:

- Understanding existing polycrystalline installations on UK properties

- Evaluating the performance of older systems

- Making decisions about system upgrades or replacements

- Understanding the evolution of solar technology

For new installations in 2025, monocrystalline panels represent the industry standard, offering superior efficiency, performance, and long-term value. Our MCS-accredited team exclusively specifies modern monocrystalline technology for all new solar installations.

Understanding solar panel types empowers you to select the optimal technology for your property. Whether you're considering a domestic solar panel installation across Nottingham, Derby, Leicester, or Lincoln solar installations, or planning a commercial solar panel system for UK businesses, knowledge of panel technologies forms a crucial foundation for system performance and return on investment.

Need Expert Solar Panel Advice?

Our MCS-accredited engineers provide impartial guidance on panel selection tailored to your specific property and energy needs

Get Your Free Assessment Contact Our TeamUnderstanding Solar Panel Types

Solar panels generate electricity through photovoltaic cells that convert sunlight into useable electrical current. Both monocrystalline and polycrystalline technologies utilise silicon as their semiconductor material, yet their manufacturing methods create distinct differences in performance, appearance, and cost.

Silicon solar cells work by creating an electric field when photons from sunlight knock electrons loose from silicon atoms. This electron movement generates direct current (DC) electricity, which inverters then convert to alternating current (AC) for household or business consumption. The quality and structure of silicon crystals directly influence how efficiently this conversion occurs.

The crystalline silicon photovoltaic market dominates global solar installations, accounting for over 95% of residential and commercial systems. Within this category, monocrystalline and polycrystalline panels represent the two primary cell technologies, each offering specific advantages depending on installation requirements and budget constraints.

What Are Monocrystalline Solar Panels?

Monocrystalline solar panels feature cells manufactured from single, pure silicon crystals. The Czochralski process grows these crystals as continuous cylindrical ingots, which are then sliced into thin wafers. This manufacturing method creates highly uniform crystal structures that facilitate superior electron movement and energy conversion efficiency.

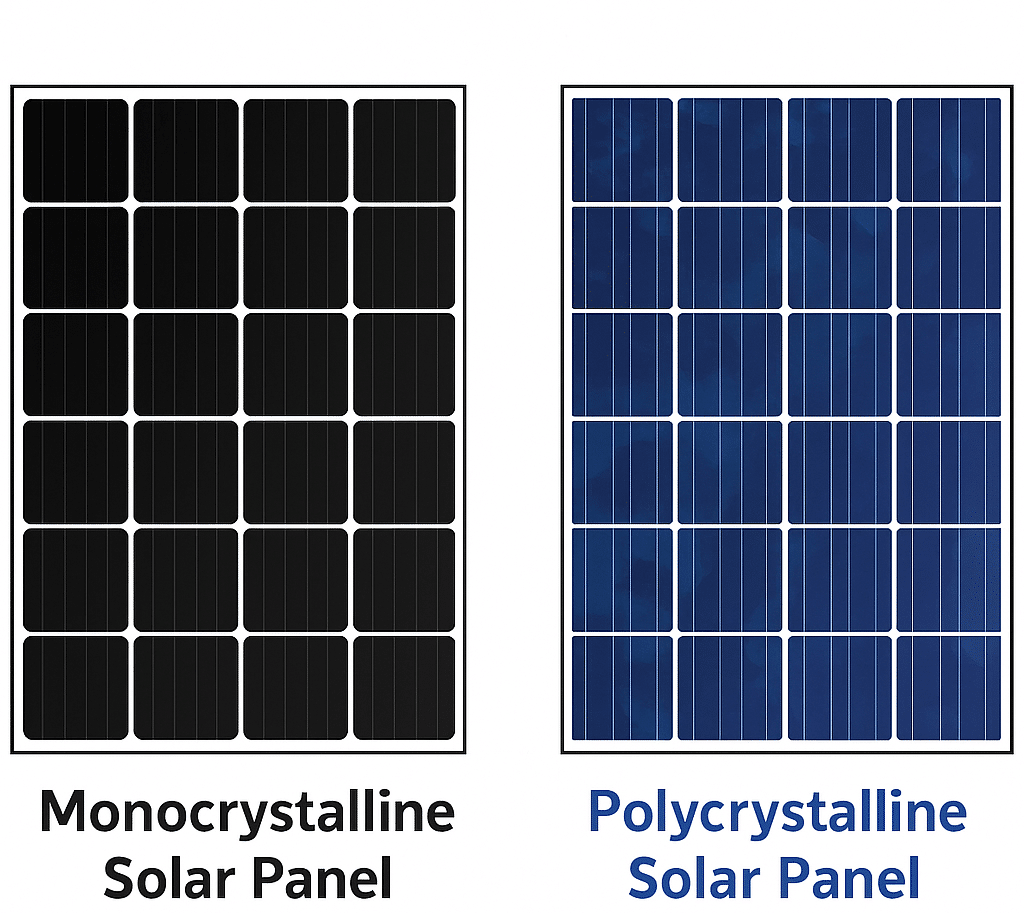

Visual Characteristics and Appearance

Monocrystalline cells display a distinctive uniform black or dark blue colour with rounded edges, resulting from the cylindrical crystal cutting process. Many property owners prefer their sleek, consistent aesthetic, particularly on visible roofs where appearance matters. The black surface integrates seamlessly with darker roof tiles, creating a more cohesive architectural look.

Efficiency and Performance

Modern monocrystalline panels typically achieve efficiency ratings between 19% and 23%, with premium models exceeding 22%. This superior efficiency means each panel generates more electricity from the same surface area compared to alternative technologies. For UK installations where roof space is often limited, this higher power density proves particularly valuable.

Monocrystalline technology also demonstrates better performance in low-light conditions, an important consideration given the UK's variable weather. The pure silicon crystal structure facilitates electron movement even when sunlight intensity drops, maintaining reasonable output during overcast periods typical of British weather patterns.

Typical Applications and Use Cases

Monocrystalline panels suit properties with:

- Limited roof space: Maximises output where available area constrains system size

- High energy demands: Businesses or households requiring substantial generation capacity

- Aesthetic priorities: Properties where visual appearance influences design decisions

- Shading challenges: Locations with partial shading where every percentage point of efficiency matters

- Premium specifications: Projects prioritising maximum long-term performance and output

Commercial installations on warehouses, solar panels for office buildings, and industrial solar systems for manufacturing frequently specify monocrystalline technology to maximise return per square metre of available roof space. Our commercial solar panel installation projects across the East Midlands demonstrate the value of efficiency-focused panel selection in space-constrained scenarios. For agricultural applications, explore our farm solar panel systems.

What Are Polycrystalline Solar Panels?

Polycrystalline solar panels (also called multicrystalline) are manufactured by melting multiple silicon fragments together. Rather than growing single crystals, molten silicon is poured into square moulds and allowed to cool. This simpler production method creates cells containing numerous silicon crystals rather than one continuous structure.

Manufacturing Process and Structure

The polycrystalline manufacturing process involves less energy and fewer production steps than monocrystalline fabrication. Molten silicon cools in moulds to form ingots, which are then cut into square wafers. This method generates less waste since square cells tessellate perfectly without unused gaps, though the multiple crystal boundaries affect electron flow compared to monocrystalline cells.

Distinctive Blue Appearance

Polycrystalline panels exhibit a characteristic blue colour with a speckled or fragmented appearance, reflecting light differently due to the multiple crystal structures. Some property owners find this aesthetic less appealing than monocrystalline's uniform black finish, though panels mounted on less visible roofs make appearance considerations secondary to performance and cost.

Efficiency Range and Output

Polycrystalline panels typically achieved efficiency ratings between 15% and 18%. Whilst lower than monocrystalline alternatives, this efficiency level still provides excellent energy generation for most UK properties. The performance difference becomes less significant when adequate roof space allows installation of additional panels to compensate for the modest efficiency gap. Understanding common solar panel problems helps maintain optimal efficiency regardless of panel type.

Temperature coefficients for polycrystalline panels are slightly less favourable, meaning they lose marginally more efficiency during hot weather. However, UK climate conditions rarely push panel temperatures high enough to make this difference operationally significant.

Historical Cost-Effective Solar Solutions

The simpler manufacturing process and lower material waste made polycrystalline panels more affordable per watt of capacity when they were in production. For budget-conscious projects or installations with ample roof space, polycrystalline technology delivered strong value, providing substantial energy savings despite the lower efficiency rating.

Domestic installations on larger properties, agricultural buildings, and warehouses with extensive roof areas often benefited from polycrystalline panels. The cost savings allowed larger system capacities, potentially generating more total electricity than a smaller premium monocrystalline array would produce. Explore our guide to choosing the right solar panel for detailed selection criteria. Additionally, understanding the key benefits of solar panels for homes and businesses helps inform technology decisions.

Key Differences Between Monocrystalline and Polycrystalline Panels

Understanding the specific differences helps match panel technology to your installation requirements, budget, and performance expectations. The following comparison highlights critical factors affecting long-term system economics and satisfaction.

| Feature | Monocrystalline | Polycrystalline |

|---|---|---|

| Efficiency Range | 19-23% (higher power per m²) | 15-18% (moderate output) |

| Cost per Watt | Current market standard | No longer manufactured |

| Lifespan | 25-30+ years | 25-30 years |

| Degradation Rate | ~0.3-0.5% annually | ~0.5-0.8% annually |

| Appearance | Uniform black, sleek finish | Blue with speckled pattern |

| Low-Light Performance | Superior (better for UK weather) | Good (slightly lower in diffuse light) |

| Temperature Coefficient | -0.35% to -0.40% per °C | -0.40% to -0.45% per °C |

| Best For | All new installations (industry standard 2025) | Understanding existing systems (discontinued) |

| Manufacturing | Single crystal growth (Czochralski) | Molten silicon cooling in moulds |

| Warranty Typical | 25-30 year performance guarantee | 25 year performance (when available) |

Efficiency Context: A 4% efficiency difference means a monocrystalline system might require 15-20% fewer panels to generate the same annual output. On a typical 4kW UK domestic installation, this could represent 2-3 fewer panels, reducing required roof area by approximately 4-6 square metres.

Performance in Real-World Conditions

Laboratory efficiency ratings provide useful comparisons, but real-world performance depends on multiple factors including installation angle, shading, soiling, temperature, and local climate patterns. Both technologies perform reliably across UK weather conditions, with monocrystalline panels maintaining a modest advantage during overcast periods.

For East Midlands installations, typical annual solar irradiation ranges from 950 to 1,050 kWh per square metre. Both panel types convert this available energy effectively, with system design, orientation, and shading prevention often proving more influential than cell technology in determining total output. Understanding grid-tied vs off-grid solar systems helps determine optimal configuration for your needs.

Which Type Is Best for UK Homes and Businesses?

Current Market Reality (2025): For all new solar installations, monocrystalline panels represent the industry standard and only available option from major manufacturers. Polycrystalline panels are no longer in production, making this decision relevant primarily for those maintaining or evaluating existing systems rather than new installations.

The information below provides context for understanding older systems and explains why monocrystalline technology became the universal choice.

Understanding why monocrystalline technology displaced polycrystalline panels helps explain modern solar system performance and guides decisions about system upgrades or replacements. The transition reflects technological advancement and manufacturing efficiency improvements that made higher-performance panels cost-competitive.

Why Monocrystalline Became the Universal Standard

Several factors drove the complete market transition to monocrystalline technology:

- Manufacturing efficiency improvements: Advances in production reduced monocrystalline costs to levels competitive with polycrystalline panels

- Superior efficiency: Higher output per square metre became increasingly valuable as roof space constraints grew

- Better performance characteristics: Enhanced low-light performance and lower degradation rates improved long-term returns

- Aesthetic preferences: Uniform black appearance proved more popular with homeowners and commercial property owners

- Longer warranties: Manufacturing confidence enabled extended performance guarantees

Historical Context: When Polycrystalline Panels Were Appropriate

Before discontinuation, polycrystalline panels served specific market segments effectively. Understanding these applications helps evaluate existing installations:

Polycrystalline Panels Were Chosen When:

- Large roof areas provided ample space for lower-efficiency panels

- Upfront cost minimisation was the primary purchasing criterion

- Aesthetic appearance was secondary to functional energy generation

- Budget constraints prevented investment in higher-efficiency technology

- Agricultural or industrial buildings prioritised cost over space efficiency

These installations continue operating effectively across the UK. Existing polycrystalline systems require no immediate replacement—they provide reliable energy generation throughout their rated lifespan. Maintenance and monitoring remain identical to monocrystalline systems.

Recommendations for New Installations in 2025

For any new solar installation, monocrystalline panels offer:

- Maximum energy output per square metre of roof space

- Superior performance in UK's variable weather conditions

- Extended warranty coverage (typically 25-30 years)

- Lower degradation rates ensuring sustained output over decades

- Better low-light performance for overcast conditions

- Modern aesthetics with uniform black appearance

- Wide availability and competitive pricing

Our expert solar installation services specify premium monocrystalline panels from tier-one manufacturers, ensuring optimal performance and long-term reliability for both domestic and commercial applications.

Other Factors to Consider Before Choosing

Panel technology selection forms just one component of system design. Several additional factors influence overall performance, cost, and satisfaction with your solar investment.

Installation and Roof Conditions

Roof characteristics often dictate practical panel choices regardless of theoretical preferences. Structural capacity must support panel weight plus mounting systems and potential snow loads. Most domestic roofs accommodate either technology without reinforcement, though older buildings may require structural assessment.

Roof orientation significantly impacts energy generation. South-facing roofs optimise output in the UK, though east and west orientations still deliver strong performance. Panel efficiency becomes more critical when roof orientation is suboptimal—higher-efficiency monocrystalline cells help compensate for less ideal positioning.

Shading presents a significant challenge to solar performance. Even partial shade reduces output substantially, affecting polycrystalline panels slightly more than monocrystalline alternatives. Professional shading analysis using specialised software identifies problematic trees, chimneys, or neighbouring structures. In heavily shaded locations, microinverters or power optimisers mitigate impact regardless of panel type.

Professional Site Survey: MCS-accredited installers conduct comprehensive assessments evaluating roof condition, orientation, shading patterns, structural capacity, and electrical infrastructure. This analysis informs accurate system sizing and panel recommendations tailored to your property's specific constraints and opportunities.

Current UK Solar Installation Costs (2025)

Domestic Systems

3-4kW: £5,000-£8,000 installed

Complete system including inverter, mounting, and commissioning

Cost Per Watt

£1.25-£2.00/watt installed

Varies with system size and installation complexity

Commercial Installations

Economies of scale apply

Per-watt costs reduce on larger arrays

Modern monocrystalline panel pricing reflects manufacturing maturity and competitive market dynamics. These costs represent complete, professionally installed systems using tier-one monocrystalline panels with appropriate warranties and performance guarantees.

Aesthetic Preferences and Property Considerations

Visual appearance matters more for some properties than others. Listed buildings, conservation areas, or prominent homes may prioritise aesthetics, favouring monocrystalline's uniform appearance. Conversely, panels on less visible roofs or agricultural buildings make appearance secondary to performance and cost considerations.

Some homeowners prefer polycrystalline's distinctive blue colour, finding it more recognisably "solar" in appearance. Personal preference is valid—you'll live with these panels for decades, so satisfaction with their appearance contributes to overall happiness with your investment.

Planning regulations occasionally restrict solar installations in sensitive areas. Local authorities may impose conditions affecting panel size, placement, or appearance. Understanding these constraints before panel selection prevents costly redesigns. Our experienced team navigates planning requirements ensuring compliant installations across protected and standard properties.

Long-Term Maintenance and Warranty

Both panel technologies require minimal maintenance—typically just annual inspections and occasional cleaning. Monocrystalline panels' lower degradation rates mean they maintain higher output percentages over decades, potentially delivering 3-5% more total lifetime energy production. Learn more about proper solar panel cleaning techniques to maximise efficiency.

Warranty terms reflect expected longevity. Premium monocrystalline panels often include 25-30 year performance warranties guaranteeing 85-90% of original output after 25 years. Polycrystalline warranties typically covered 20-25 years at similar performance thresholds when available. Manufacturing warranties covering defects usually span 10-15 years for both technologies.

Inverter lifespan (typically 10-15 years) often becomes the limiting factor for system longevity rather than panel degradation. Budgeting for eventual inverter replacement applies regardless of panel choice. Our comprehensive maintenance and support services ensure your system operates optimally throughout its lifespan. Regular solar system health checks identify potential issues before they impact performance.

Space-Constrained Properties

- Prioritise monocrystalline efficiency

- Maximise output per square metre

- Consider microinverters for shading

- Professional design optimises layout

Large Roof Areas

- Monocrystalline maximises generation potential

- Superior long-term economics

- Lower degradation benefits compound over time

- Quality installation remains critical

Premium Performance

- Monocrystalline for maximum efficiency

- Superior low-light performance

- Extended warranty coverage

- Lowest degradation rates

Understanding Solar Investment Returns in the UK

Payback periods for quality monocrystalline solar installations in the UK depend on energy consumption patterns, electricity tariffs, system size, and export arrangements through the Smart Export Guarantee (SEG).

Key Variables Affecting Your Returns

Self-Consumption Rates

Higher daytime usage improves returns by reducing grid electricity purchases

Electricity Tariffs

Current UK rates (averaging £0.24-0.27/kWh in 2025) significantly impact savings

Export Rates

SEG tariffs vary from 4p to 15p per kWh depending on supplier

System Size

Appropriate sizing maximises self-consumption without excess export at lower rates

Battery Storage

Adding battery storage for solar systems increases upfront costs but can reduce grid reliance by 70-80%

Long-Term Value: Monocrystalline systems benefit from superior degradation rates (0.3-0.5% annually) and extended warranties (typically 25-30 years). After payback, systems generate essentially free electricity for the remainder of their lifespan, with minimal maintenance requirements.

Commercial projects demand detailed financial modelling accounting for tax implications, capital allowances, and operational savings. Our team provides comprehensive analysis helping you evaluate system sizing and maximise investment returns through optimal configuration. Explore solar panel funding options for businesses and smart commercial solar investment strategies to enhance project viability.

Professional Guidance from Spectrum Energy Systems

Panel selection represents just one element of successful solar implementation. System design quality, component matching, installation workmanship, and ongoing maintenance all significantly impact performance and returns. Working with experienced, accredited installers ensures your investment delivers expected benefits.

At Spectrum Energy Systems, established in 2011, our MCS-accredited engineers bring over a decade of solar installation experience across residential and commercial projects throughout the East Midlands. We maintain manufacturer independence, recommending panel technologies based solely on your specific requirements rather than inventory priorities or supplier relationships.

Comprehensive System Design

Our design process evaluates numerous factors beyond panel type:

- Energy consumption analysis: Understanding your usage patterns optimises system sizing and configuration

- Roof assessment: Detailed surveys identify optimal panel placement, accounting for structural considerations and shading

- Inverter selection: Matching inverter technology to panel configuration ensures efficient power conversion

- Future expansion: Designs accommodate potential commercial battery storage systems or EV charging infrastructure integration

- Grid connection: Managing DNO applications and G98/G99 compliance for smooth commissioning

- Financial modelling: Accurate projections help you understand expected returns and payback timelines

We explain trade-offs clearly, helping you balance priorities like upfront cost, space constraints, aesthetic preferences, and long-term performance objectives. This consultative approach ensures you make informed decisions aligned with your circumstances rather than generic recommendations.

Quality Components and Installation

Panel quality matters as much as technology choice. We specify tier-one manufacturers with proven UK track records, robust warranties, and established service networks. This focus on reliability prevents the frustration of dealing with manufacturers who withdraw from markets or fail to honour warranty claims.

Installation quality profoundly affects system performance and longevity. Our NICEIC-certified electrical work ensures safe, compliant installations meeting all UK regulations. Mounting systems use appropriate fixings for your roof type, preventing water ingress whilst accommodating thermal expansion. Proper cable management and weatherproofing protect electrical connections from the UK's variable climate. View our solar installation case studies to see real-world examples of quality installations across various property types, including solar panels for schools and colleges, retail solar installations, and solar solutions for property developers.

Ready to Discuss Your Solar Project?

Schedule a free site survey and receive impartial advice on the best panel technology for your property. Our team provides transparent guidance helping you maximise your solar investment.

Request Your Free Quote Call 0115 773 7575Ongoing Support and Monitoring

Solar systems require minimal maintenance, but periodic inspections and performance monitoring ensure optimal operation. We provide comprehensive aftercare including system commissioning, monitoring setup, and maintenance packages. This support helps you identify and resolve issues quickly, protecting your investment's long-term value.

Modern monitoring platforms track generation in real-time, alerting you to performance drops or technical faults. Understanding your system's output patterns helps validate the panel technology choice and confirms predicted savings materialise. Our team remains available for technical support, system optimisation, and future expansion planning. For businesses requiring comprehensive information, review our complete business solar panel guide and explore innovative solar projects for enterprises.

Frequently Asked Questions

Making Your Final Decision

Understanding the differences between monocrystalline and polycrystalline solar panels provides valuable context for evaluating solar technology, even though the choice between them no longer exists for new installations. This knowledge helps you assess existing systems, understand technological evolution, and appreciate why modern monocrystalline panels deliver superior value.

For new solar investments in 2025, monocrystalline panels represent the only available option from major manufacturers, offering optimal combination of efficiency, performance, and long-term value. This market consolidation reflects genuine technological advancement rather than arbitrary preference—manufacturing improvements made higher-efficiency panels cost-competitive whilst delivering measurably better performance.

For Existing Polycrystalline System Owners: Your panels remain effective and require no immediate replacement. Continue regular maintenance and monitoring—these systems deliver reliable energy generation throughout their rated 25-30 year lifespan. Consider system upgrades or replacements only when panels reach end-of-life or when efficiency improvements justify investment through detailed financial analysis.

Modern Solar Investment Considerations

With panel technology standardised on monocrystalline cells, other factors now differentiate solar installations:

- Panel efficiency ratings: Modern monocrystalline panels range from 19-23% efficiency, with premium models exceeding 22%

- Cell technology: PERC, TOPCon, and heterojunction (HJT) variants offer performance differences within monocrystalline category

- Manufacturer quality: Tier-one brands provide better warranties, service networks, and long-term reliability

- System design: Inverter selection, mounting systems, and cable sizing significantly impact performance

- Installation quality: MCS-accredited installers ensure safe, compliant work meeting UK regulations

Working with experienced, accredited installers ensures your technology choice integrates appropriately with inverter selection, mounting systems, electrical infrastructure, and grid connection requirements. This holistic approach delivers optimal performance and maximises your solar investment's value.

Remember: Panel technology selection is just one component of system performance. Installation quality, component matching, system design, and ongoing maintenance collectively determine your solar investment's success. Working with experienced, accredited installers ensures optimal results regardless of panel choice.

Additional Considerations for Future-Proofing

Solar technology continues evolving, with emerging innovations like bifacial panels, PERC cells, and heterojunction technology enhancing efficiency further. However, current monocrystalline technologies remain proven, widely supported, and economically viable for UK installations. Waiting for "next generation" technologies often means delaying valuable energy savings and environmental benefits available today. Explore our next-generation solar technology solutions and solar installations for modern constructions.

Consider future plans when selecting panels. If you anticipate adding battery storage, EV charging, or smart home energy management systems, ensure your initial system capacity accommodates these additions. Higher-efficiency monocrystalline panels may provide headroom for increased electricity consumption without requiring additional roof space. Learn about solar panel incentives for UK homeowners to maximise your investment value.

System expandability also matters. Some roof layouts allow future panel additions, whilst others exhaust available space with the initial installation. Discussing long-term plans with your installer ensures your panel choice supports potential future expansion.

Conclusion: Understanding Solar Technology Evolution

Understanding the differences between monocrystalline and polycrystalline solar panels provides valuable perspective on solar technology evolution and helps evaluate existing installations. Whilst polycrystalline panels are no longer manufactured for new installations, millions of these systems operate effectively across UK properties, delivering reliable energy generation throughout their design life.

For new solar investments in 2025, monocrystalline technology represents the industry standard, offering superior efficiency, enhanced low-light performance, and proven long-term reliability. This market consolidation simplifies purchasing decisions whilst ensuring access to the highest-performing solar technology at competitive pricing.

The transition from polycrystalline to monocrystalline dominance demonstrates solar industry maturation—manufacturing advances made premium technology accessible at mainstream pricing, benefiting all solar investors through improved system performance and returns.

Spectrum Energy Systems brings over a decade of solar installation experience helping East Midlands homeowners and businesses navigate technology decisions and system design. Our manufacturer-independent advice ensures recommendations serve your best interests, specifying optimal monocrystalline panels from tier-one manufacturers with proven UK track records. Consult our comprehensive ultimate guide to installing solar PV systems for detailed technical insights and explore renewable power solutions for companies.

Start Your Solar Journey Today

Professional guidance ensures optimal results whether you're installing new monocrystalline panels or maintaining existing systems. Contact our team for a free consultation and site assessment. We'll evaluate your property, discuss your priorities, and recommend the solar solution that best meets your needs.

Get Your Free Solar Quote Book Your Site SurveyAbout Spectrum Energy Systems: Established in 2011, we're MCS-accredited solar installers serving Nottingham, Derby, Leicester, Lincoln and the wider East Midlands. Our experienced engineers design and install tailored solar solutions for homes and businesses, ensuring maximum performance and return on investment. Learn more about our expertise or explore our homeowner resources for comprehensive solar guidance. We also specialise in commercial building solar installations, solar systems for car dealerships, and solar panels for public sector buildings.